Founder Mike Li worked in the IT industry up until 5 years ago when he was inspired by a video that highlighted a unique use of 3D printing for children’s prosthetics. Motivated to apply medical 3D printing for prosthetics in order to help others, he and other local makers volunteered their time to create and customize prosthetics for patients.

HK Make Club is made up of local makers who are keen on technology and driven by innovation. They initiated their prosthetic campaign by using their talents to create prosthetic arms and hands.

Now, they are influential promoters of 3D printing technologies among local HK hospitals and medical institutions such as Prince of Wales Hospital.

Customized prosthetics require unique and precision fitting parts that traditionally require lengthy and expensive iterations. These types of prosthetics have been unattainable to most of its intended patients due to high costs.

Before adopting 3D printing, prosthetic production struggled with:

1. Inability to produce large quantities due to custom parts and requirements of plaster molds.

2. Long lead times and involved iterations due to the need for new molds alongside changes.

3. High cost due to time and resources used.

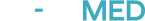

Utilizing the Raise3D N2, HK Make Club was able to:

1. Eliminate physical prototypes and create final production parts directly.

2. Use 3D CAD data to make the custom and precision accurate parts.

3. Reduce costs by over 90%

Company: Hong Kong Maker Club

Industry: 3D Printed Prosthetics

Interviewee: Mike Li (Li, Zaimin)

Title: Founder of Maker Club

Process:

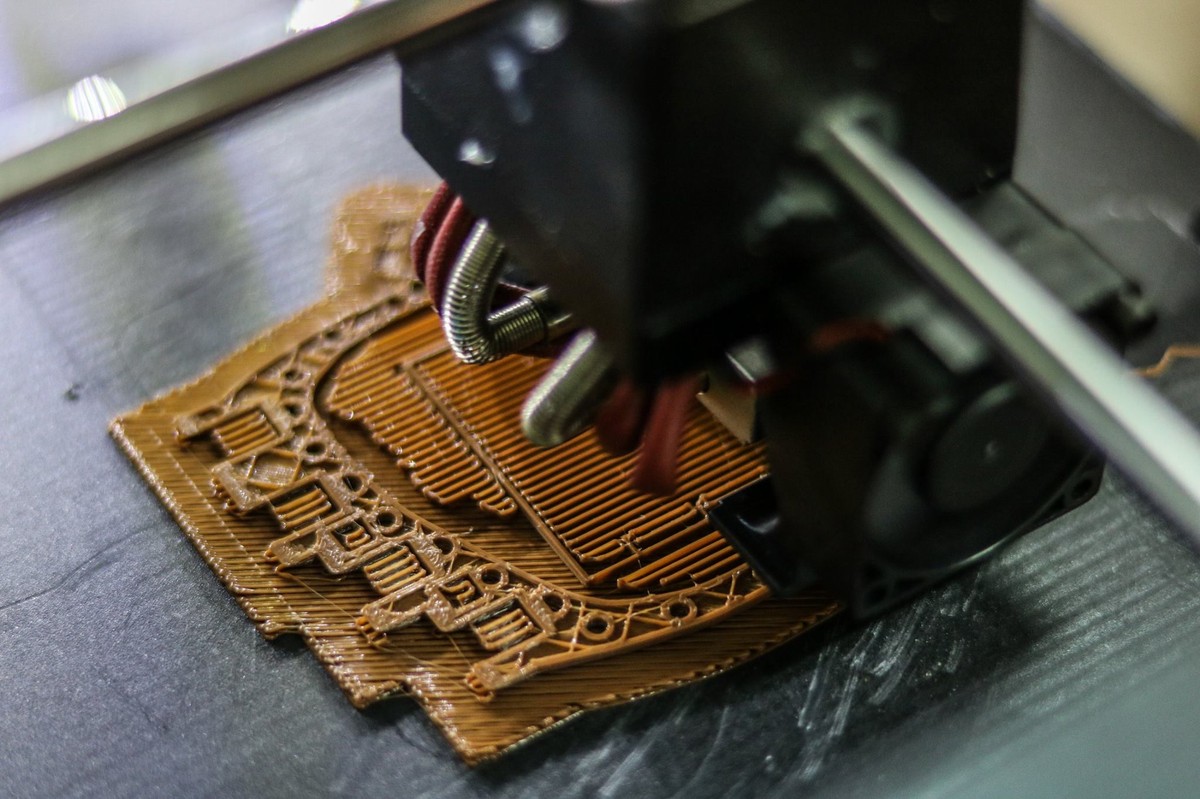

The prosthetic creation process begins by creating a CAD template. With the aid of Chang Hsian-Liang, the regarded “God of Open Source Prosthesis” in Taiwan, Mike Li customizes a CAD design specifically for their patient. The structure, dimensions, palms, fingers, and overall geometry is uniquely customized according to the patient’s healthy hand.

After optimizing the CAD model and layout, Mike uses the Raise3D N2 to print all the necessary parts. The printed parts are primarily made from PLA or ABS material and are used to create the major structures such as the palms and fingers. Cords and springs are added during assembly and are used to transfer forces from wrist to finger joints.

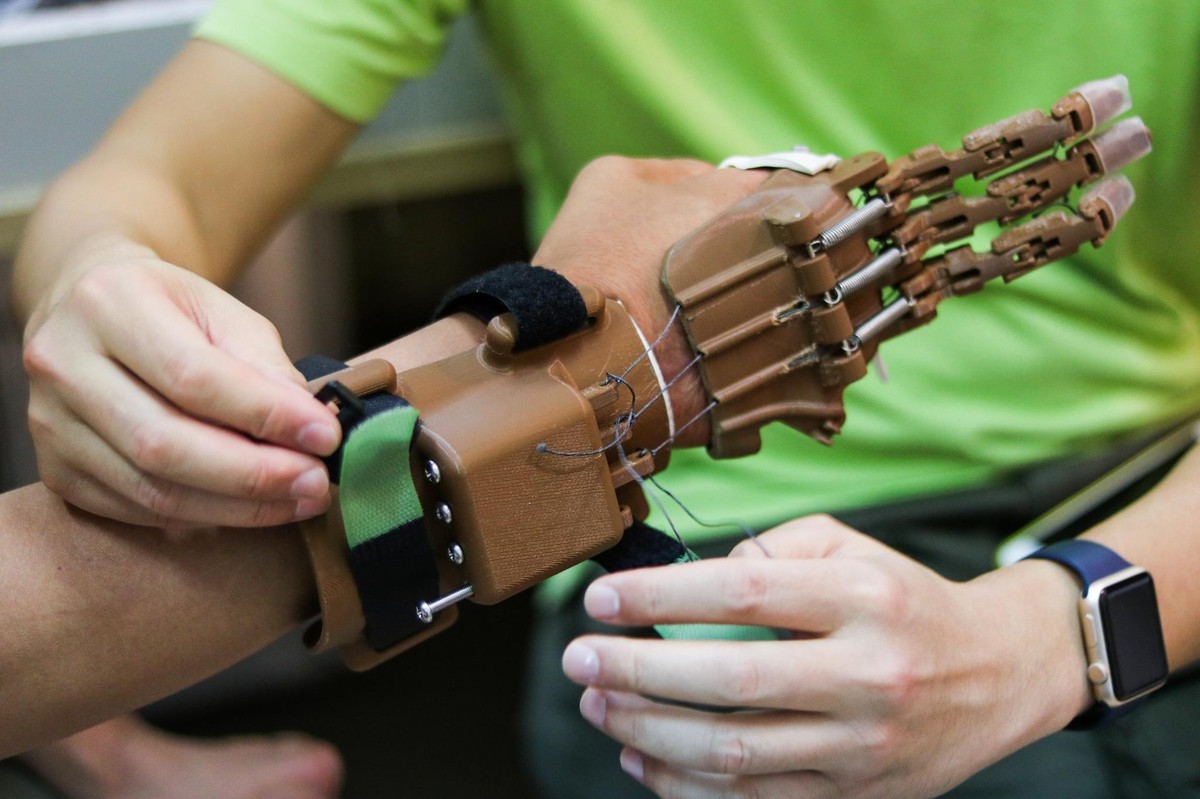

A patient wearing the palm prosthesis can control the grip turning their wrist, which will tighten the cords and close the fingers. The spring on the top of the palm forces fingers to reset its position when losing their grasp. The exposed screw will adjust the tension and can control the power of the grip for a wide variety of applications.

Challenges:

Before 3D printing was applied in prosthetics, the only process available was the traditional casting process. In this method, the process involves an initial evaluation, measurements, cast making, diagnostic test socketing, dynamic fitting/alignment, and cosmetic restoration. This involved process requires many iterations and the process is lengthy and inflexible. Each cast is made by molding with plaster and will require a new mold any time an adjustment is made; affecting the overall timeline and cost of the finished prosthetic piece. The cost of customized and functional prosthetics can cost up to $128,000. However, many amputees cannot afford even the more inexpensive traditional options at $2,500.

Solution:

Using the Raise3D N2 printer, the HK Maker Club has been able to supply over 100 3D printed prosthetic hands within Hong Kong and Africa. By optimizing their procedure with 3D printed parts, a final production part with custom fitting and functional fingers retails around 250 dollars.

From beginning to end, the process is about 100 hours which includes: scanning, designing, adjustments, printing, and installation. Printing alone is 20 hours which traditionally would have needed to have active labor hours to create. Additionally, the PLA or ABS material that is used is much lighter than traditional casted prosthetics. In return, the patients like Eric (below) can wear their prosthetic for a longer period of time due to the comfort of the custom fit and lightweight material properties.

Eric suffered from peripheral vasoconstriction, a narrowing of the blood vessels, which resulted in the loss of his fingers. The local hospital once provided him a non-functional plastic glove that did not fit his hand and offered a prosthetic hand which he could not afford.

Thanks to Mike Li, Eric was able to receive a customized affordable prosthetic.