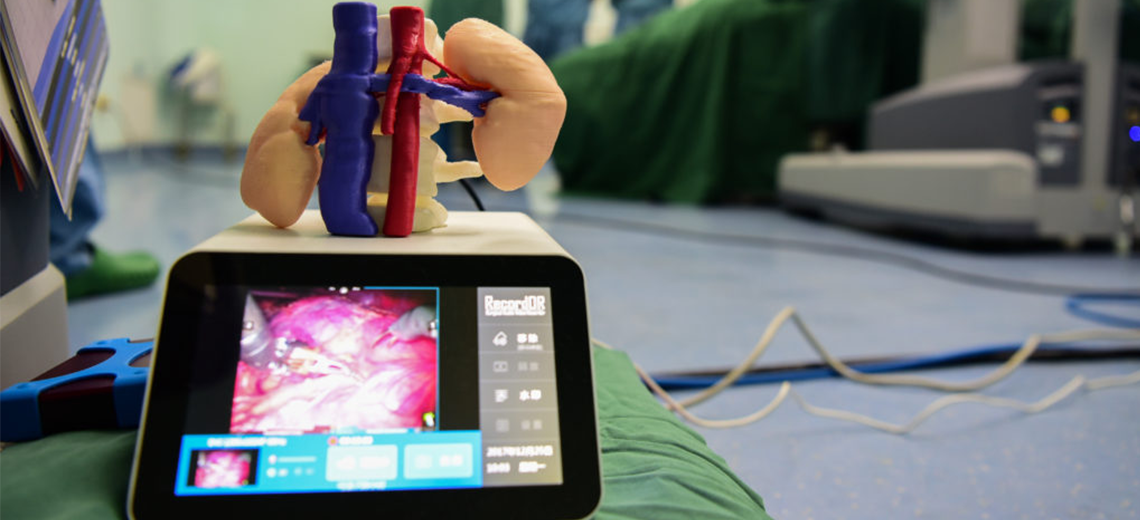

In medical field, the evolution of new technologies is opening up new horizons, presenting innovative solutions that are increasingly closer to the needs of the patient.

The development of biomaterials for application in medicine is one of the biggest research challenges in materials science.

These revolutionary materials are defining a new era in medical device manufacturing, enabling customized solutions and targeted treatments through the integration of additive manufacturing processes with FFF technology.

Bioresorbable Polymers: what are they?

Biomaterials have natural or synthetic origin and can interact with biological systems temporarily or permanently, constituting a possible alternative to the treatment, repair and replacement of tissues or organs. The classes of materials used to make implantable devices include metals, ceramics and, more recently, polymers.

Biodegradable polymers are organic compounds that can be broken down by biological agents, such as bacteria or fungi, into simpler, more natural substances. On the other hand, we speak of bioresorbable polymers when they can be absorbed by the human body without leaving harmful residues.

These polymers offer an answer to the need for temporary medical devices, which perform their function during a specific period and subsequently dissolve naturally.

In recent decades, in the field of orthopaedic applications, there has been an increase in interest in bioresorbable polymers, materials that, once implanted in vivo, degrade over time, releasing by-products that are then excreted and metabolised in a way that is harmless to the body.

Advanced Medical Applications

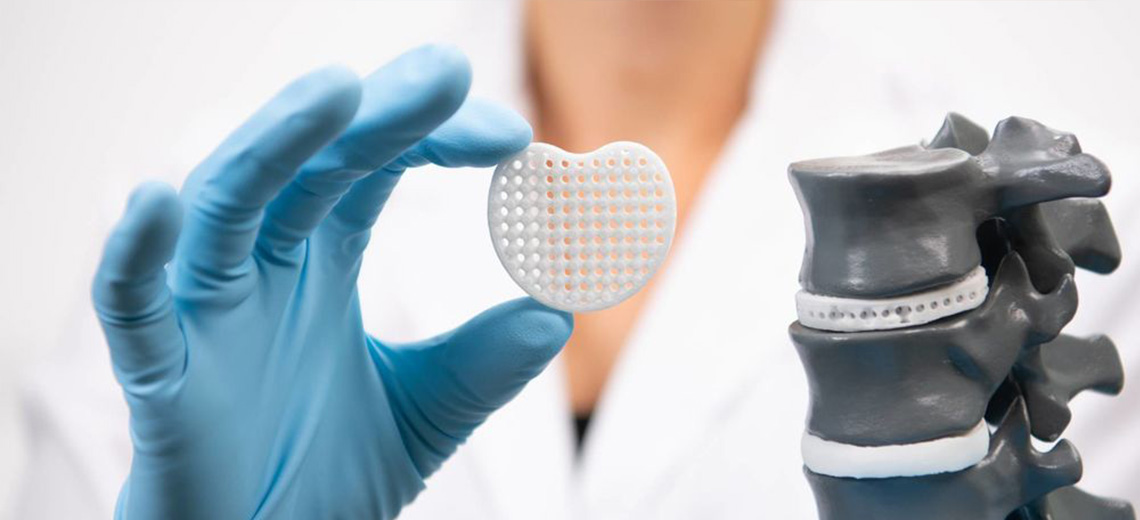

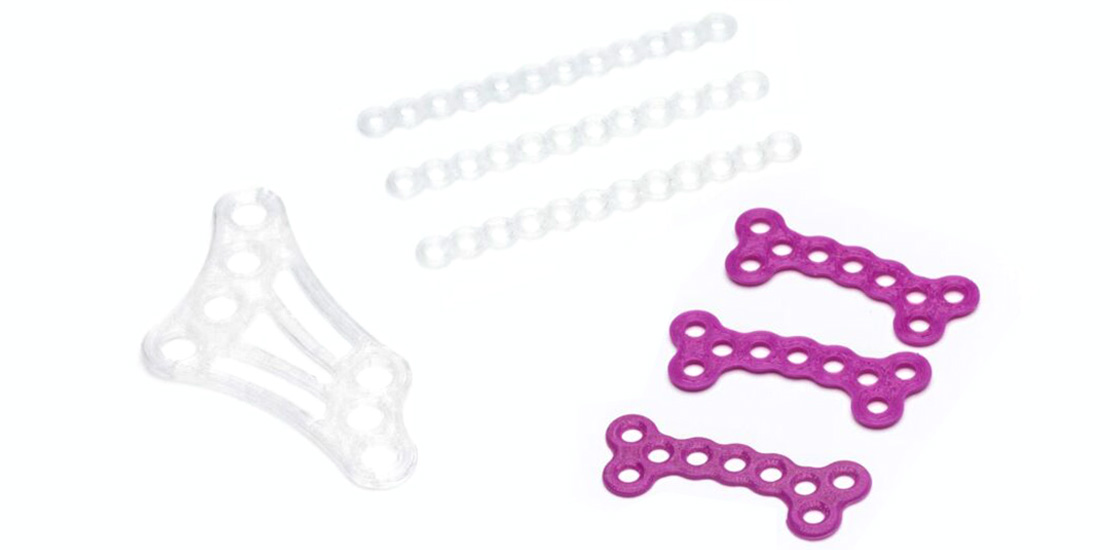

Used since the 1960s as suture materials, bioresorbable polymers have recently also been widely used in traumatology, tissue regeneration and the controlled release of drugs. In orthopaedic surgery, examples of bioresorbable devices used for temporary tissue fixation are: sutures, anchors/nails for fixation of soft tissues to bone, screws for ligament repair, pins/plates/screws for fixation of fractures.

What are the benefits?

The advantages offered by their use have become important:

No Additional Surgery: One of the main advantages of these polymers is their ability to gradually disappear without the need for additional surgery for their removal, as well as being compatible with magnetic resonance imaging (MRI). This reduces patient discomfort and the risk of post-operative complications.

Reduced Recovery Time: Medical devices 3D printed with bioresorbable polymers can more closely adapt to the patient's needs, speeding up recovery time and minimizing the downtime associated with more invasive surgeries.

Lower Risk of Infection: The temporary nature of these devices reduces the risk of long-term infections, as the material naturally degrades preventing foreign bodies from remaining in the body. They avoid complications that can occur with metal implants, such as corrosion, release of metal ions.

Intelligent Delivery Systems: They can be used for the delivery of bioactive agents such as antibiotics.

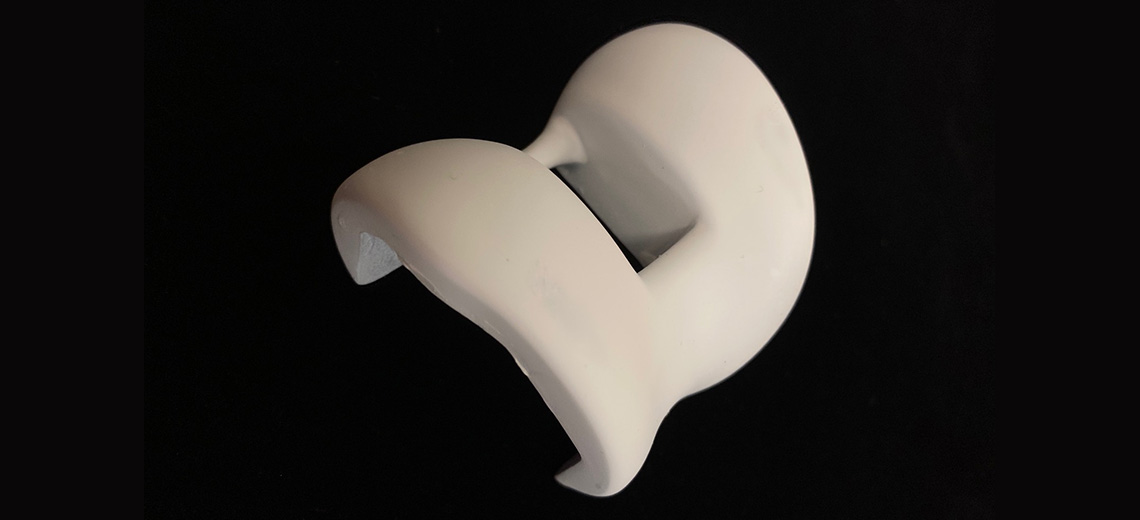

Combining all these properties with 3D printing encourages customization and experimentation with new designs and materials. The flexibility of the technology allows medical professionals to tailor solutions for patients with unique needs, pushing the boundaries of therapeutic possibilities.

Prosthetics, implants, and support structures can be specifically designed to fit patients' individual anatomical needs, significantly improving the efficacy and tolerability of these devices.

In terms of the market, an estimated 600,000+ implants have been produced using 3D printing, and this is expected to reach over 4 million by the end of 2027 at a CAGR of 26.7%.

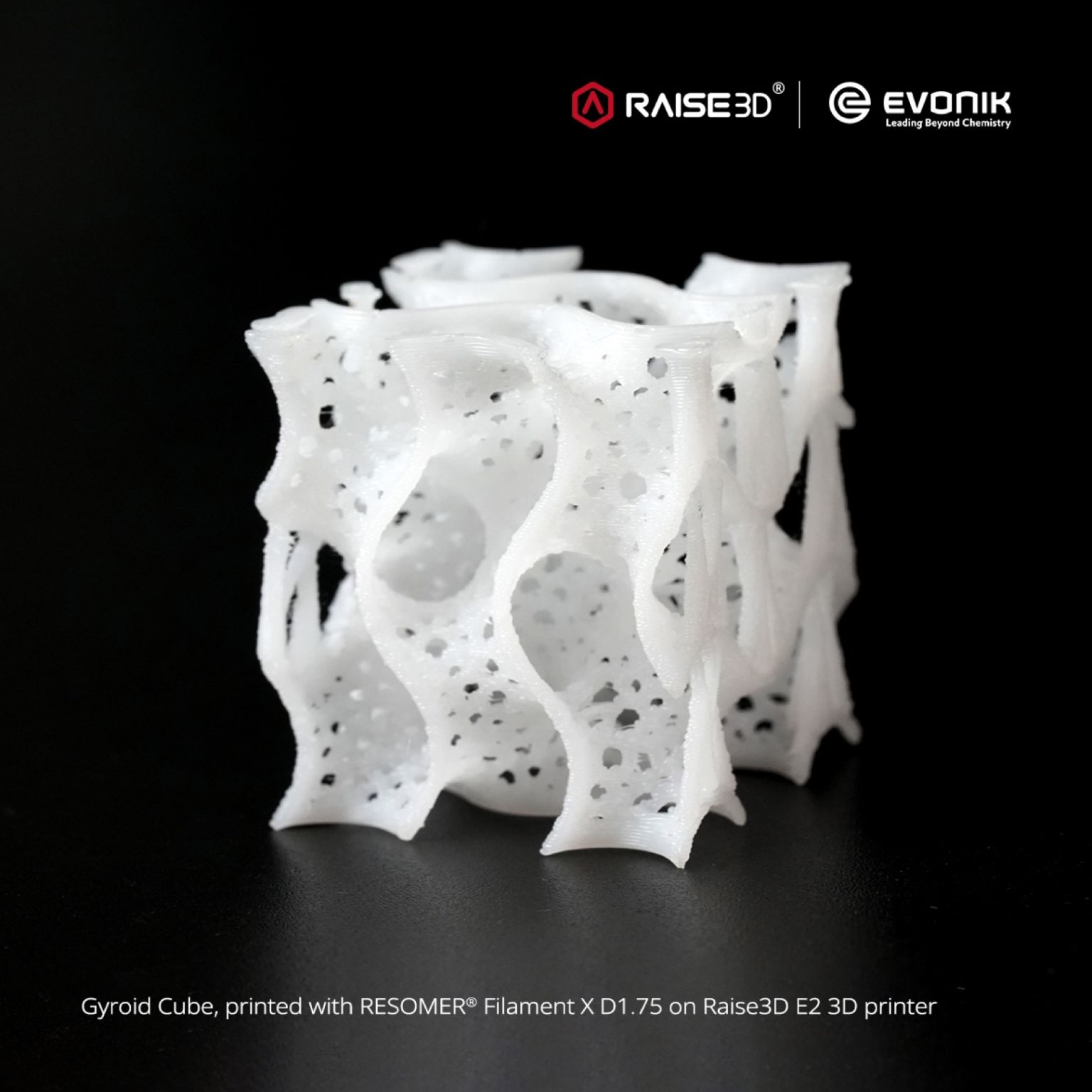

Thanks to Raise3D's collaboration with Evonik, a global leader in biomaterials for medical implants, it is now possible to easily and successfully print its RESOMER® filament on any Raise3D E2 3D printer.

Raise3D's Open Filament Program (OFP) system has made available the following filament profiles:

- Evonik RESOMER® Filament C D1.75 (PCL)

- Evonik RESOMER® Filament L D1.75 (PLLA)

- Evonik RESOMER® Filament X D1.75 (PDO)

- (Coming soon) Evonik RESOMER® LG D1.75 Filament (PLGA)

A wide range of standard and customizable filaments with a strong track record in terms of efficacy, biocompatibility, safety and ease of supply in over 30 years of commercial use

Ready for the next revolution in medicine?